3D Printer:

A 3D printer is a type of additive manufacturing device that creates three-dimensional objects by layering materials on top of each other based on a digital design. It enables the production of physical objects from digital models using a variety of materials such as plastics, metals, ceramics, and more.

The technology used in 3D printers varies depending on the specific type of printer, but the most common technology is called fused deposition modeling (FDM) or fused filament fabrication (FFF). FDM/FFF printers work by extruding a heated thermoplastic filament through a nozzle, which moves along a predefined path determined by the digital model. The extruded material cools down and solidifies, layer by layer, to form the final object.

Other technologies used in 3D printing include stereolithography (SLA), digital light processing (DLP), selective laser sintering (SLS), selective laser melting (SLM), and electron beam melting (EBM). These technologies employ different methods such as curing liquid resin with UV light, sintering or melting powdered materials with lasers, or using an electron beam to melt metal powders.

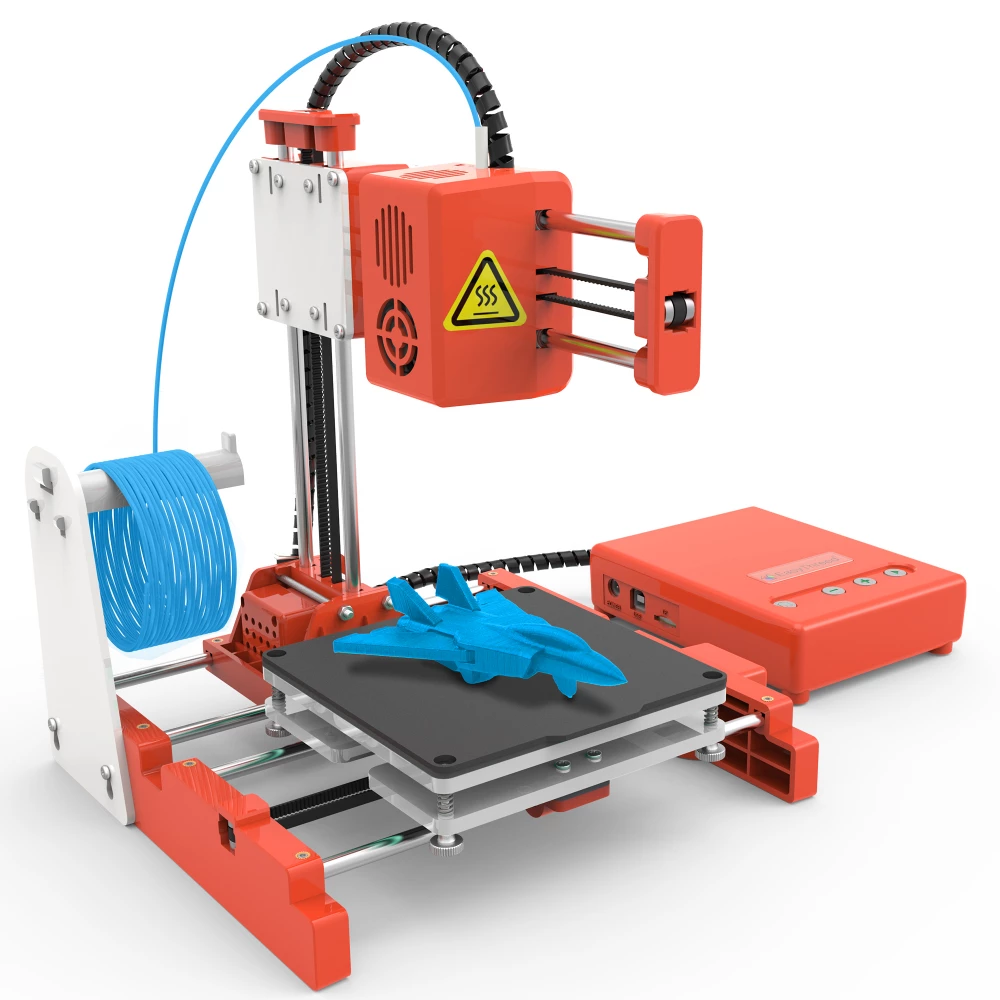

Structure of 3D Printer:

The structure of a 3D printer can vary depending on the model and manufacturer, but it typically consists of the following components:

- Frame: The rigid structure that holds the printer together and provides stability during the printing process.

- Build Platform: The surface where the object is built layer by layer.

- Print Head/Extruder: The part responsible for heating the filament and depositing it accurately to create the object.

- Filament Spool: The storage for the filament material used in FDM printers.

- Control Panel: A user interface for controlling the printer settings and initiating the printing process.

- Motors and Belts: These drive mechanisms move the print head, build platform, or other parts of the printer in precise directions as commanded by the digital model.

- Cooling System: Some printers incorporate fans or cooling mechanisms to quickly cool down the printed layers.

- Power Supply: Provides the necessary electrical power for the printer to operate.

Applications:

The uses of 3D printers are vast and continually expanding. Some common applications include:

- Prototyping: 3D printing allows for rapid and cost-effective prototyping, enabling designers and engineers to create physical models and test their designs before mass production.

- Manufacturing: In certain industries, 3D printers are used for small-scale manufacturing of end-use parts, custom components, and tooling.

- Education: 3D printers are increasingly being used in educational settings to teach students about design, engineering, and manufacturing concepts.

- Medical and Dental: 3D printing has revolutionized the medical field, allowing for the production of patient-specific implants, prosthetics, anatomical models, and surgical instruments.

- Art and Design: Artists and designers utilize 3D printers to create intricate sculptures, jewelry, fashion accessories, and other artistic creations.

- Architecture and Construction: 3D printing is used in architecture to create scale models, architectural prototypes, and even full-scale structures.

- Aerospace and Automotive: These industries employ 3D printing for rapid prototyping, lightweight components, and complex geometries that are otherwise challenging to manufacture.

These are just a few examples, but the potential applications of 3D printing are virtually limitless, and it continues to transform various industries by enabling faster, more efficient, and customized manufacturing processes.